What Is a Press Brake?

If you’re in the metal fabrication industry, you’ve probably heard the term press brake. But what is a press brake, exactly? In this guide, we’ll cover its definition, types, working principles, and applications.

What Is a Press Brake?

What Is a Press Brake?

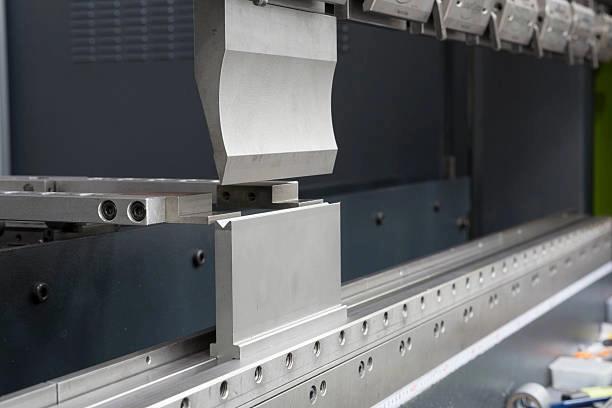

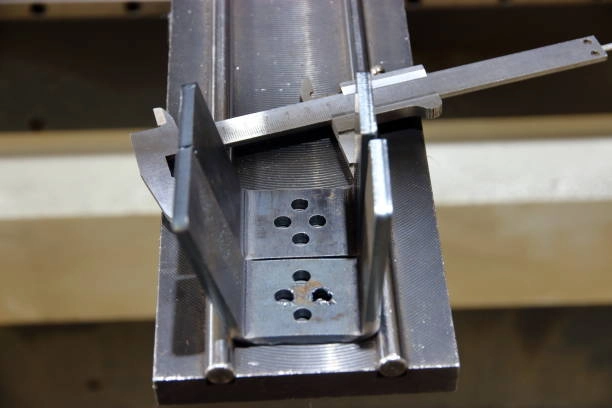

A press brake is a machine used to bend sheet metal into desired shapes. It uses a punch and die to create precise angles in metal sheets. Press brakes are widely used in manufacturing industries like automotive, construction, and appliances.

How Does a Press Brake Work?

How Does a Press Brake Work?

- Position the sheet metal on the die

- Lower the punch to apply force

- Form a precise bend with controlled angle

Types of Press Brakes

Types of Press Brakes

- Manual Press Brake: Hand-operated, best for low-volume work

- Hydraulic Press Brake: Common in industry, powered by hydraulic cylinders

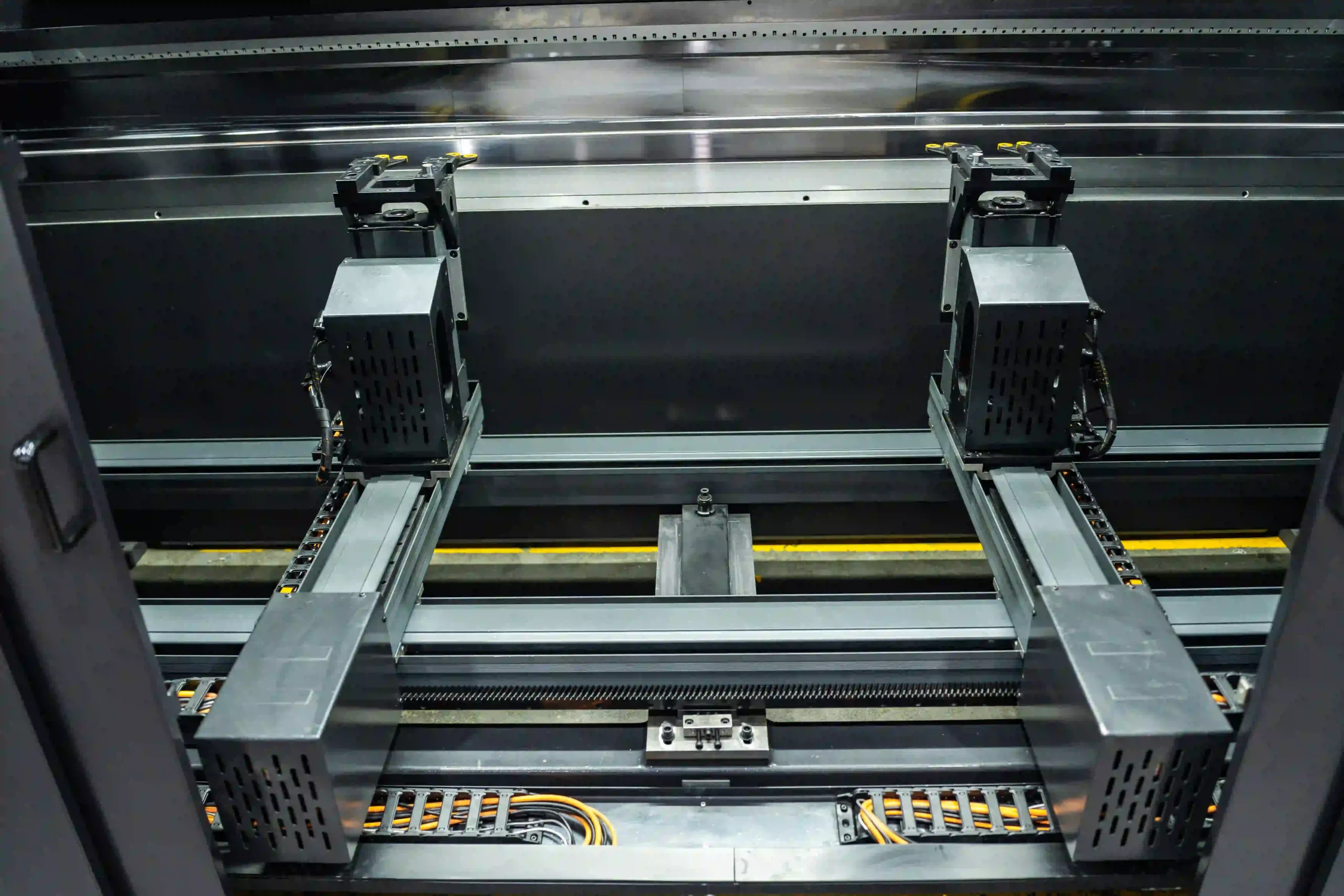

- Servo-Electric Press Brake: Uses servo motors for precision and efficiency

- Pneumatic Press Brake: Air-powered, suitable for light-duty applications

Applications of Press Brakes

Applications of Press Brakes

Press brakes are essential in various industries:

Automotive – chassis, doors, and panels

HVAC – ductwork and metal housings

Electrical – switch cabinets and enclosures

Appliances – metal covers and shells

Construction – framing parts, brackets, supports

Why Use a Press Brake?

Why Use a Press Brake?

High bending accuracy

Ideal for both mass and custom production

Compatible with CNC automation

Cost and labor efficient

Frequently Asked Questions

Frequently Asked Questions

What is a press brake?

A press brake is a machine that bends sheet metal using a punch and die system. It’s used in manufacturing for forming precise angles.

What are the types of press brakes?

The main types are manual, hydraulic, servo-electric, and pneumatic. Each suits different production needs and material types.

Where are press brakes used?

They are used in the automotive, HVAC, appliance, and construction industries to shape metal parts and components.