❓ Why do people search for LVD press brake tooling?

Because LVD press brakes are top-tier machines—and their tooling needs to match. But the official LVD tools can be expensive, slow to deliver, and difficult to customize.

That’s why many fabricators are now turning to LVD-compatible tooling—precision-ground punches and dies that work perfectly with your LVD machine, without the OEM markup.

🧩 What makes LVD tooling different?

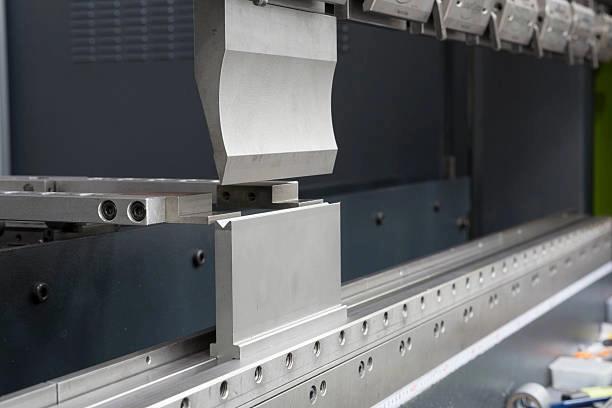

LVD press brakes often use a custom tang and clamping profile, which differs slightly from standard European or Wila systems. Key features include:

Unique tang geometry (specific to LVD clamping blocks)

Full-length or segmented upper tools

Precision-ground V dies and radius dies

Strong compatibility with CNC backgauge systems

If your machine uses LVD Easy-Form® or CADMAN® systems, tool accuracy matters even more—because it directly impacts bending compensation and angle feedback.

🛠️ What kind of LVD tooling does Machnist provide?

At Machnist, we produce a full line of LVD-style press brake tooling, including:

✅ Upper punches: 30°, 60°, 85°, gooseneck, radius, custom

✅ Lower dies: Single-V, Multi-V, radius, hemming, and non-marking

✅ Hardened and ground: ±0.01mm tolerance, HRC 48–52

✅ Segmented sets or full lengths (835mm, 415mm, 200mm)

✅ Custom-made profiles for special parts and robotic systems

We also accept drawings, original LVD part numbers, or sample tools for 1:1 replication.

💡 Real-life use case:

Client in Turkey | LVD PPEB 220T/4000

They needed segmented gooseneck punches and special Multi-V dies for stainless elevator panels—but LVD’s official tooling had a 40-day lead time.

Solution? Machnist delivered LVD-compatible tooling in 12 days—with logo engraving, scratch-resistant coating, and perfect fit on first test.

📌 When should you choose Machnist over OEM?

| Scenario | Machnist Is Ideal When… |

|---|---|

| You need custom tooling? | ✅ We make-to-spec |

| You want faster delivery? | ✅ 5–12 days, global |

| OEM cost is too high? | ✅ Save up to 40% |

| You use robotic bending? | ✅ Compatible with CADMAN® |

| You need multi-brand tooling? | ✅ We support Wila, Amada, Trumpf, LVD |

📦 How to Get Started

Just send us:

Your LVD press brake model

Tool drawings or photos

Desired V-opening, angle, or radius

Segment or full-length preference

Optional: stainless or mirror sheet needs (we’ll coat accordingly)

We’ll quote your LVD-compatible press brake tooling with precision, speed, and full support from the Machnist technical team.

🧠 Pro Tip:

Don’t mix LVD and European tooling in the same machine unless your clamping system supports both—ask us if you’re unsure. We can build hybrid clamping solutions too!