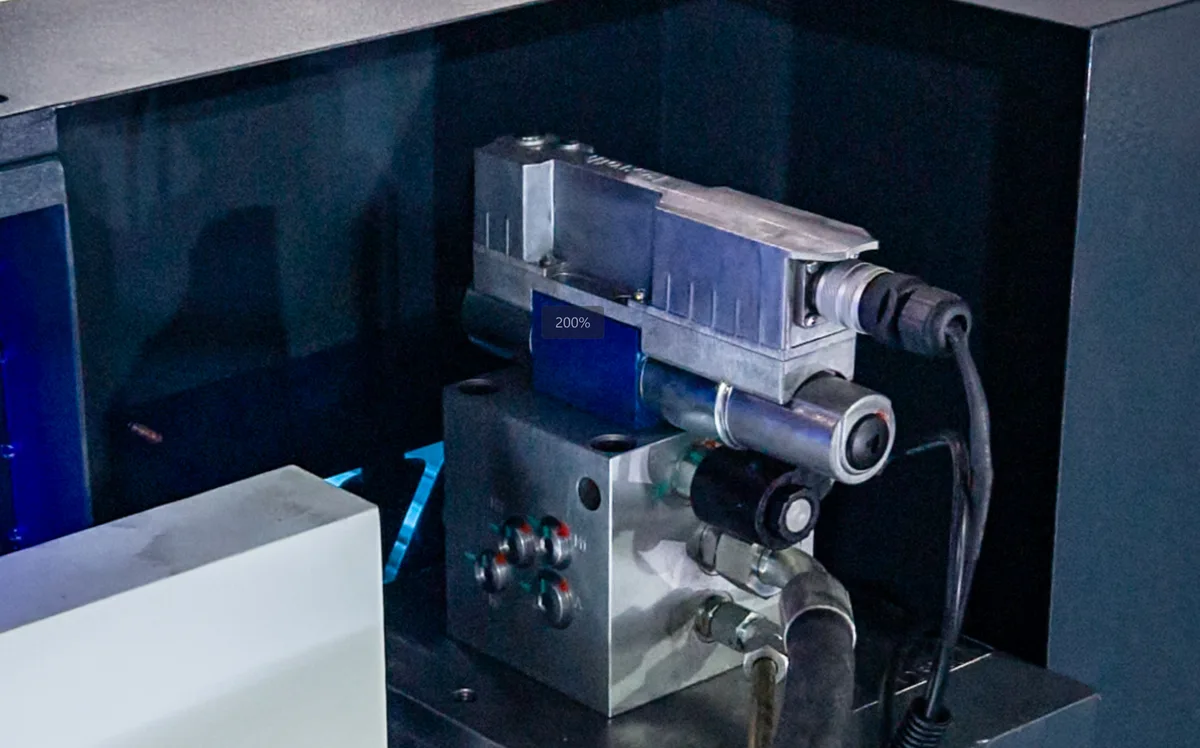

In a CNC press brake, the ability to precisely control hydraulic pressure and flow during each stage of the bending process is essential. That control comes from the proportional valve—a servo-driven device that responds to digital signals from the CNC controller.

Unlike traditional on/off valves, proportional valves adjust output continuously based on real-time system feedback. This enables:

Smooth ram movement

Precise force application

Adaptive bending speed

🔧 How Proportional Valves Work

Proportional valves receive analog or PWM signals from the CNC controller, opening partially or fully depending on the desired pressure. In a Y1/Y2 electro-hydraulic system, each cylinder’s valve adjusts independently, responding to encoder feedback.

💡 Benefits in Press Brake Applications

Greater accuracy in tonnage application across the bend

Reduced oil heating, improving efficiency and lifespan

Better dynamic response, especially for complex multi-axis bending

Quieter operation compared to traditional hydraulic systems

In robotic lines or variable thickness material jobs, this precision is essential. Proportional valves allow the machine to “think” and adjust in milliseconds.

🏭 Brands and Quality

At Machnist, we use high-performance proportional valves from trusted manufacturers like Rexroth, Yuken, and Huade, ensuring tight tolerance performance in every press brake we build.

As a performance-driven Machnist manufacturer, we integrate proportional valves in our Max and Ultra series press brakes, especially where cycle time, energy savings, and automation matter most.

Looking to upgrade or retrofit? Our Machnist supplier team can help you select the right valve, calibrate your system, and maintain top bending precision over years of service.