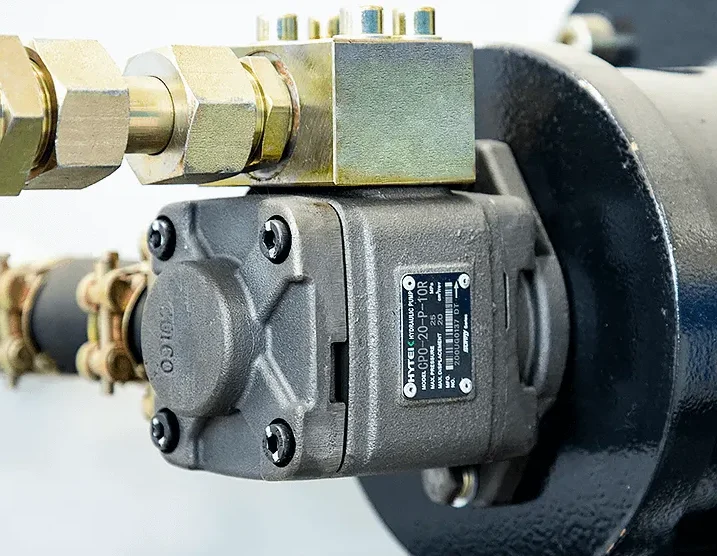

While the controller handles logic and the cylinder applies the pressure, it’s the hydraulic pump that generates the energy required for the entire bending operation. Choosing the right pump—especially in CNC press brakes—can drastically affect cycle time, oil temperature, and accuracy.

🔧 Types of Hydraulic Pumps Used in Press Brakes

1. Gear Pumps

Simple and widely used in standard press brakes

Good for steady flow and low-cost operation

Often paired with torsion bar machines

2. Variable Displacement Pumps

Adjust flow depending on pressure/load

Reduce energy consumption

Used in mid- to high-level CNC hydraulic machines

3. Servo Motor Driven Pumps (Closed-loop / Hybrid Press Brakes)

Directly controlled by servo motors

Provide dynamic pressure and flow adjustment

Enable fast return speeds and quieter operation

🛠️ Performance Factors

Flow rate (L/min): Impacts ram up/down speed and return

Noise and heat: High-efficiency pumps reduce wear and energy waste

Responsiveness: Important for high-speed or robotic bending systems

For example, increasing pump displacement improves return stroke time—but may also raise oil temperature. That’s why Machnist CNC press brakes use optimized pump-to-tonnage ratios for balance.

As a full-line Machnist manufacturer, we offer both gear-based and servo-pump models to meet customer needs across industries. If you’re running continuous jobs or automated lines, our Machnist supplier team recommends servo-driven pumps for superior speed and efficiency.

A reliable pump means consistent bending pressure, faster cycles, and better longevity. And in modern metal fabrication, that gives you a serious edge.