n sheet metal forming, operator control is critical. When handling long, wide, or flexible workpieces, it’s difficult to maintain consistent support throughout the bend. This is where press brake front sheet support arms come in.

🔩 What Are Front Sheet Support Arms?

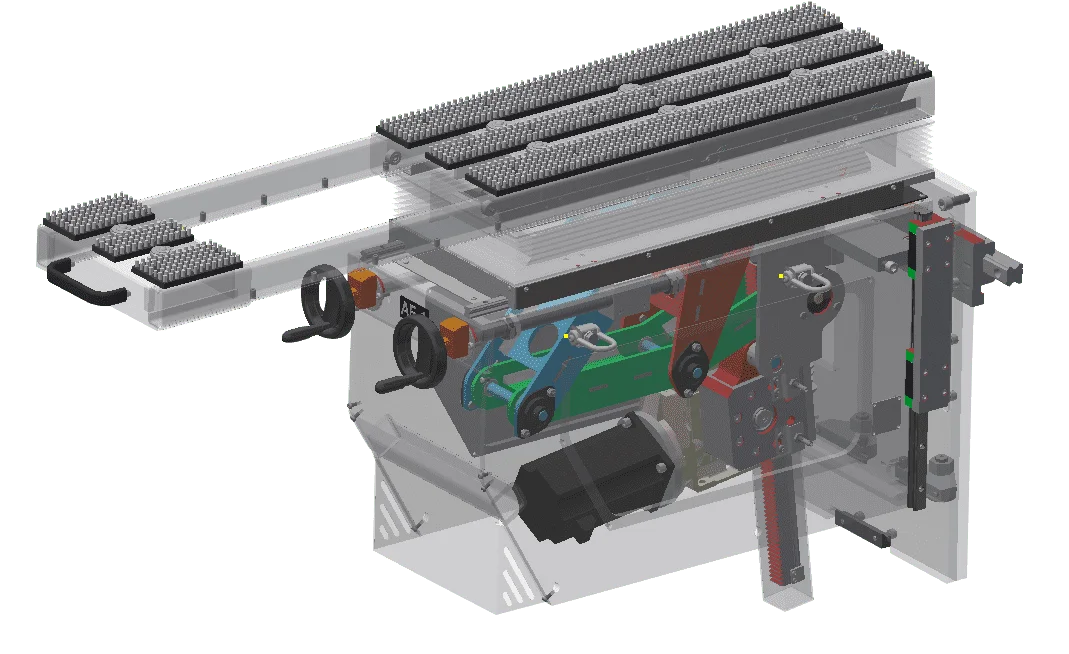

Front supports are mechanical or motorized arms mounted on the front side of the press brake. They help hold and stabilize the sheet during bending. Advanced versions use lifting and tilting axes:

➤ T1 & T2 Support Axes

T1 up/down (vertical lifting): Automatically raises or lowers to match the height of the part or die.

T1 tilting: Helps angle the sheet for special applications or ergonomic handling.

T2 up/down and tilting: Works as an additional support point for very long or flexible materials.

These axes can be controlled manually or via the CNC controller for full automation.

✅ Key Benefits

Keeps large parts level during bending

Prevents sagging or inaccurate angles

Reduces physical strain on operators

Improves speed and repeatability for long parts

At Machnist, we provide both manual and servo-driven sheet support systems integrated with our CNC press brakes. As a Machnist supplier, we help customers in kitchenware, appliance, and cabinet industries maintain bending quality and operator comfort.

If your parts are larger than 1,200 mm, or if you’re processing thin stainless or aluminum, a front sheet support system is not just helpful—it’s essential.