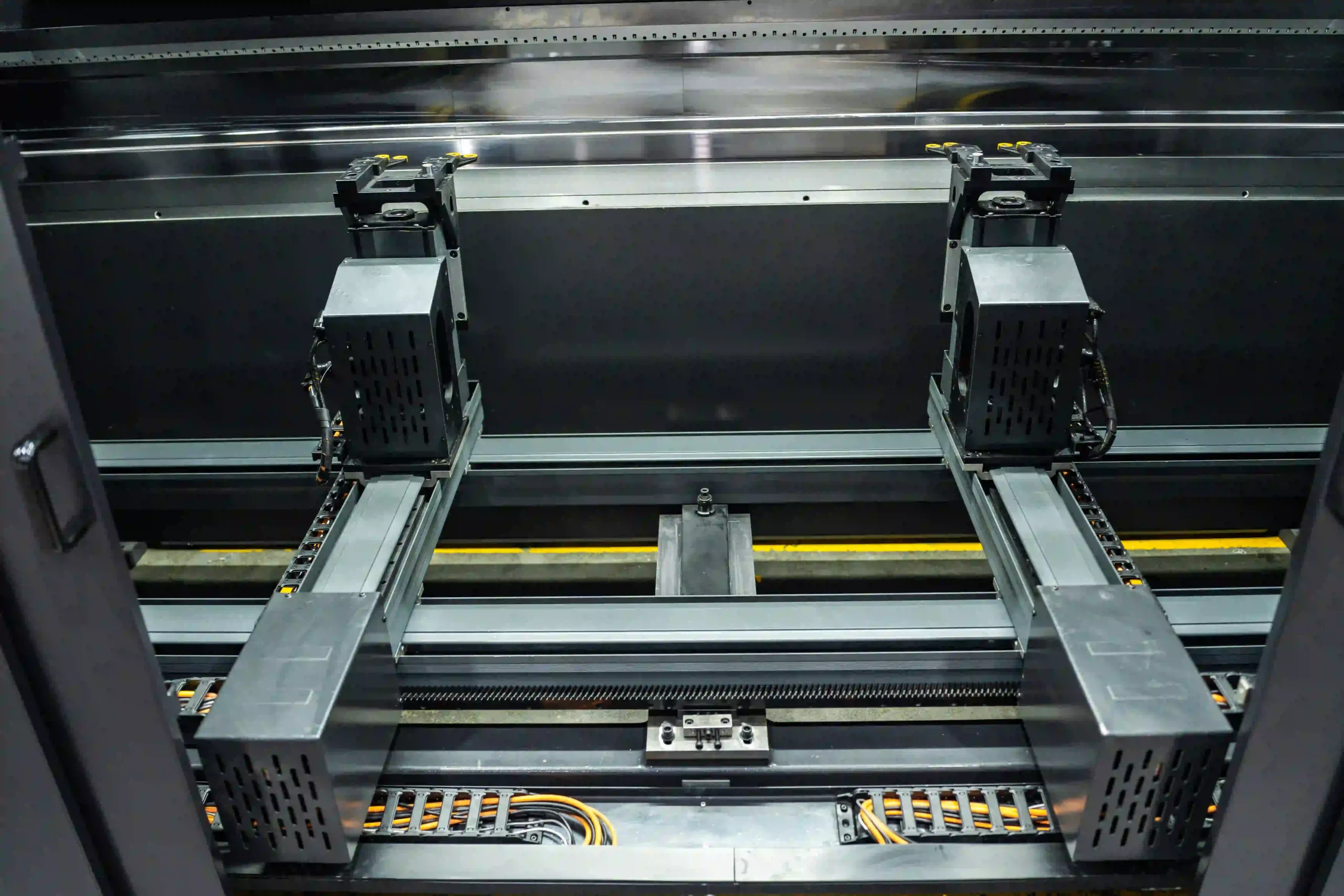

In CNC press brake operations, the back gauge plays a vital role in positioning the workpiece precisely for each bend. It’s the system responsible for determining the depth and location of the sheet metal, ensuring every bend is consistent and accurate.

🔧 Types of Press Brake Back Gauge Systems

1. 2-Axis (X, R):

This entry-level system allows:

X-axis: front-to-back positioning of the material

R-axis: vertical adjustment for different flange heights

Best for standard bending jobs and simple flange forming.

2. 4-Axis (X, R, Z1, Z2):

Ideal for more complex bends and multi-width parts:

Adds Z1/Z2: horizontal finger movement left and right

Enables multiple back gauge fingers for faster setups and part variation

3. 4+2 Axis (X, R, Z1, Z2 Manual Z):

A cost-effective hybrid:

Z1/Z2 positioning done manually

Retains auto X and R control

Useful in flexible workshops where full automation isn’t needed

4. 6-Axis (X1, X2, Y1, Y2, Z1, Z2):

For high-precision and asymmetrical part production:

Independent control of X1/X2 and Z1/Z2

Synchronized with ram movement (Y1/Y2)

Perfect for conical bends and complex part geometries

✅ Benefits of Advanced Back Gauging

Faster setups and reduced scrap

Improved repeatability

More design freedom in part development

Essential for automated or robotic press brake systems

🔩 Machnist Back Gauge Solutions

Machnist offers CNC press brakes with modular back gauge systems—from simple 2-axis to fully automated 6-axis. Our machines are built for flexibility and speed, whether you’re fabricating kitchenware or custom enclosures.