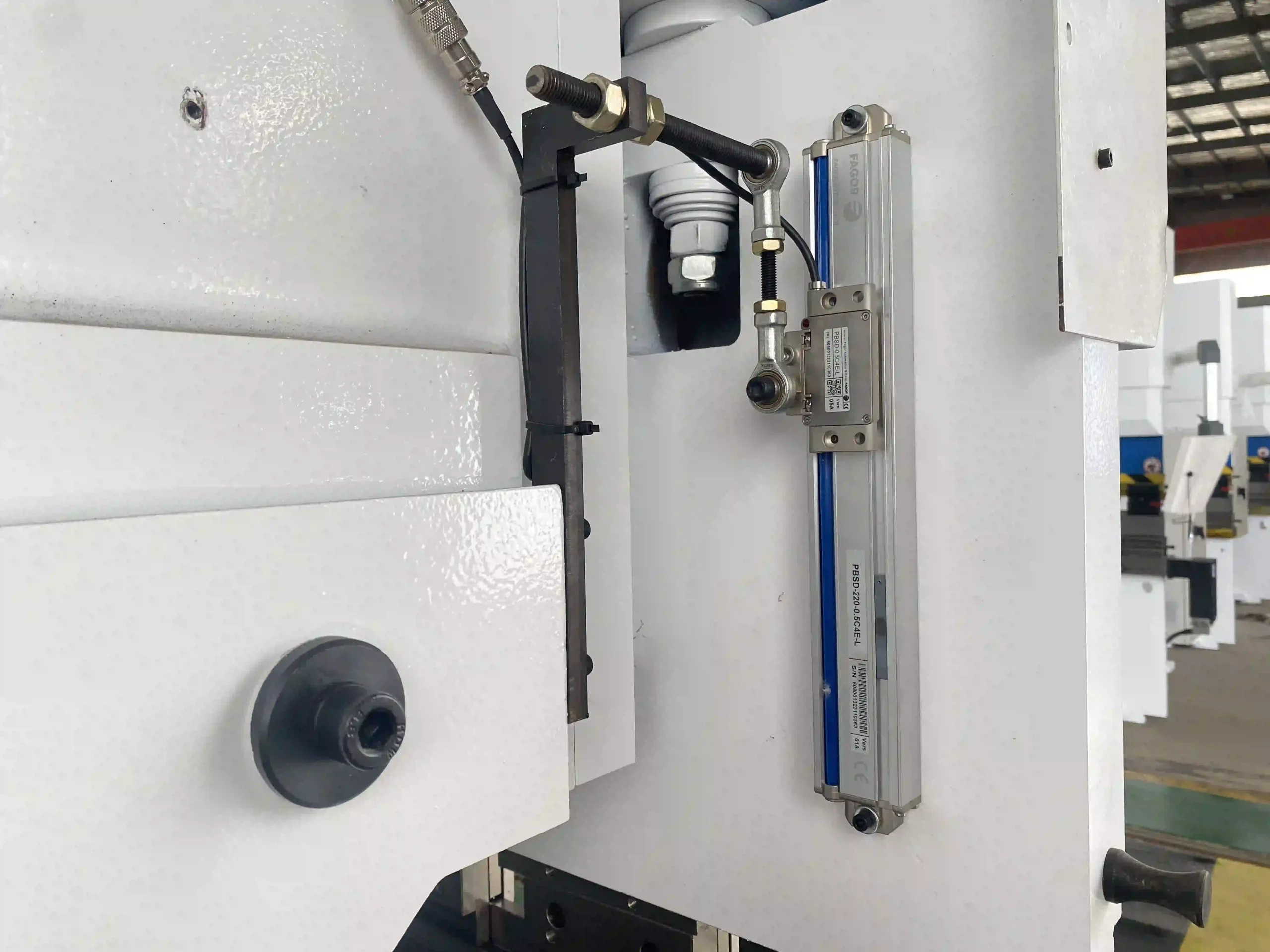

In CNC press brakes, the key to achieving repeatable, high-precision bends lies in accurate feedback. That’s where linear scales, also known as encoders, play a central role.

Mounted directly to the press brake frame and independent of hydraulic pressure, these devices measure the actual position of the ram (Y1/Y2 axes) in real time. This ensures that every movement reflects the exact intended stroke—regardless of machine wear, oil temperature, or material thickness variations.

🧠 Why Linear Scales Matter

Enable closed-loop control of ram position

Ensure ±0.01mm accuracy during bending

Detect deflection or misalignment instantly

Essential for synchronous cylinder control (especially with Y1/Y2)

🏷️ Popular Brands

Givi Misure (Italy): Known for their sealed glass encoders and high resolution

FAGOR Automation (Spain): Trusted for industrial durability and digital feedback

Heidenhain: High-end solution for robotic and aerospace environments

✅ Where They’re Used

High-precision CNC press brakes

Servo-hydraulic and servo-electric machines

Multi-axis systems requiring real-time accuracy

Robotic and unmanned production lines

At Machnist, we equip our advanced CNC press brakes with Givi or FAGOR linear scales, depending on customer preferences. As a professional Machnist manufacturer, we understand how critical accurate feedback is for reducing rejects and improving forming quality.

Whether you’re bending stainless panels, high-strength steel, or reflective aluminum, a reliable Machnist supplier solution with closed-loop feedback ensures your results match your programming—every single time.