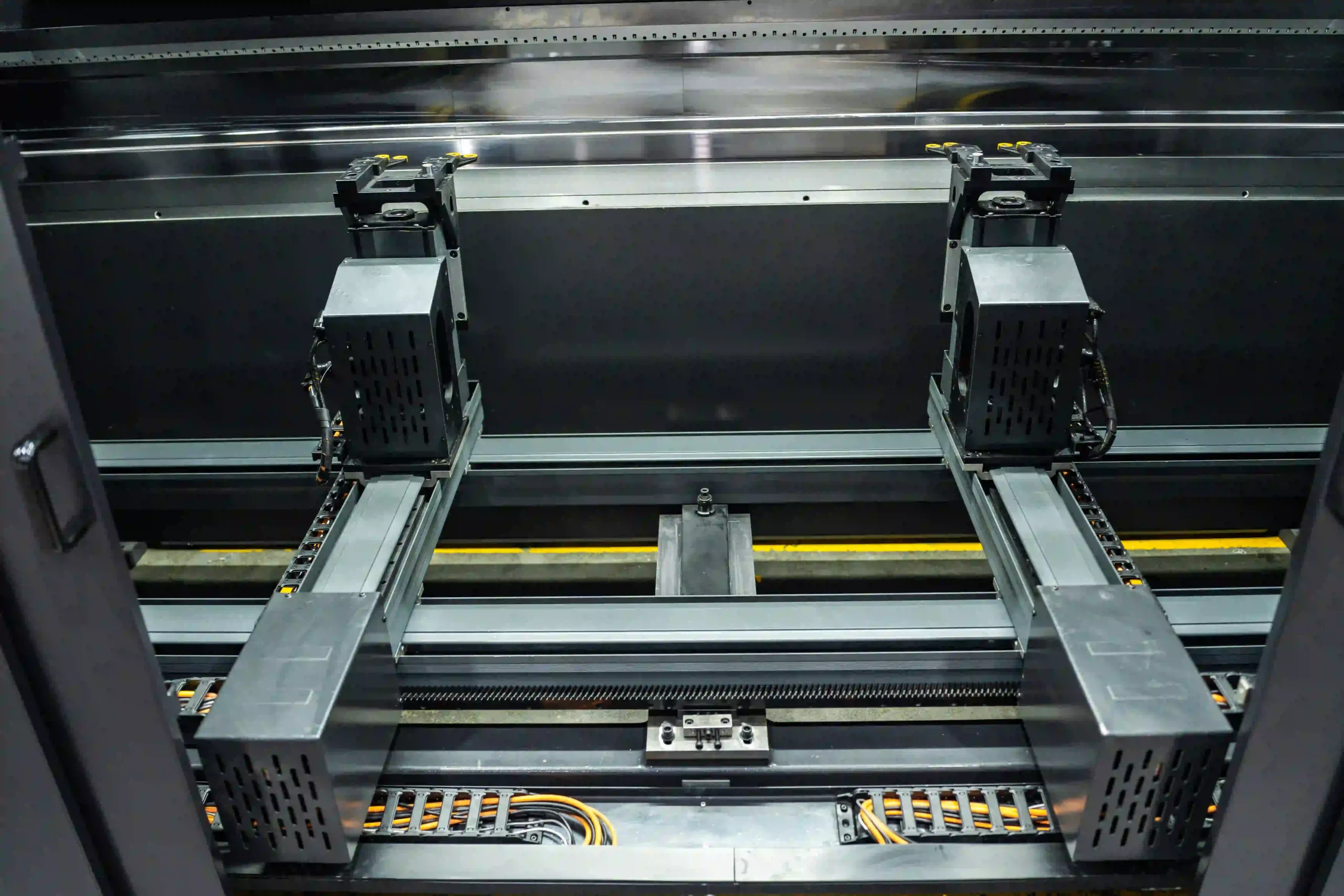

🔹 What Is a Press Brake Punch?

A press brake punch is the upper tool in a press brake machine, responsible for pressing the sheet metal into the lower die to create bends. Selecting the right punch is crucial for precision and efficiency.

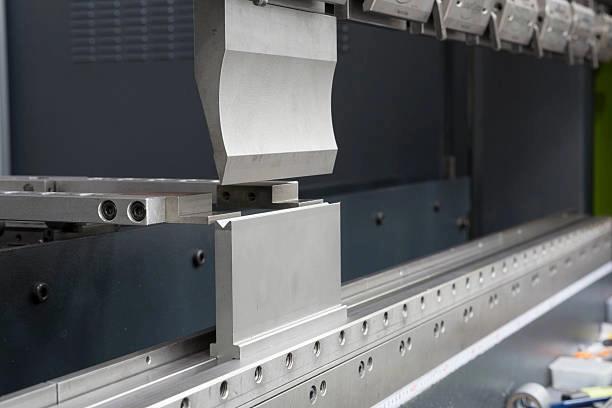

🔹 Types of Press Brake Punches

- Straight Punch: Best for basic 90-degree bends.

- Gooseneck Punch: Designed for bending boxes and deep flanges.

- Offset Punch: Creates step bends in a single operation.

- Acute Angle Punch: Used for bending sharp angles or air bending.

🔹 Press Brake Punch Material & Durability

Press brake punches are typically made from:

- Carbon Steel – Economical but wears out faster.

- Hardened Tool Steel – Offers longer lifespan and durability.

- Carbide-Tipped Punches – Best for high-volume production.

🔹 How to Choose the Right Press Brake Punch?

- Material Type – Softer metals need less pressure, harder metals require stronger punches.

- Bending Requirements – Choose punches based on the angle and depth of the bend.

- Compatibility – Ensure the punch fits your press brake tooling system 🔗.

👉 Find high-quality press brake punches here 🔗

📌 Next Article: Press Brake Dies 🔗