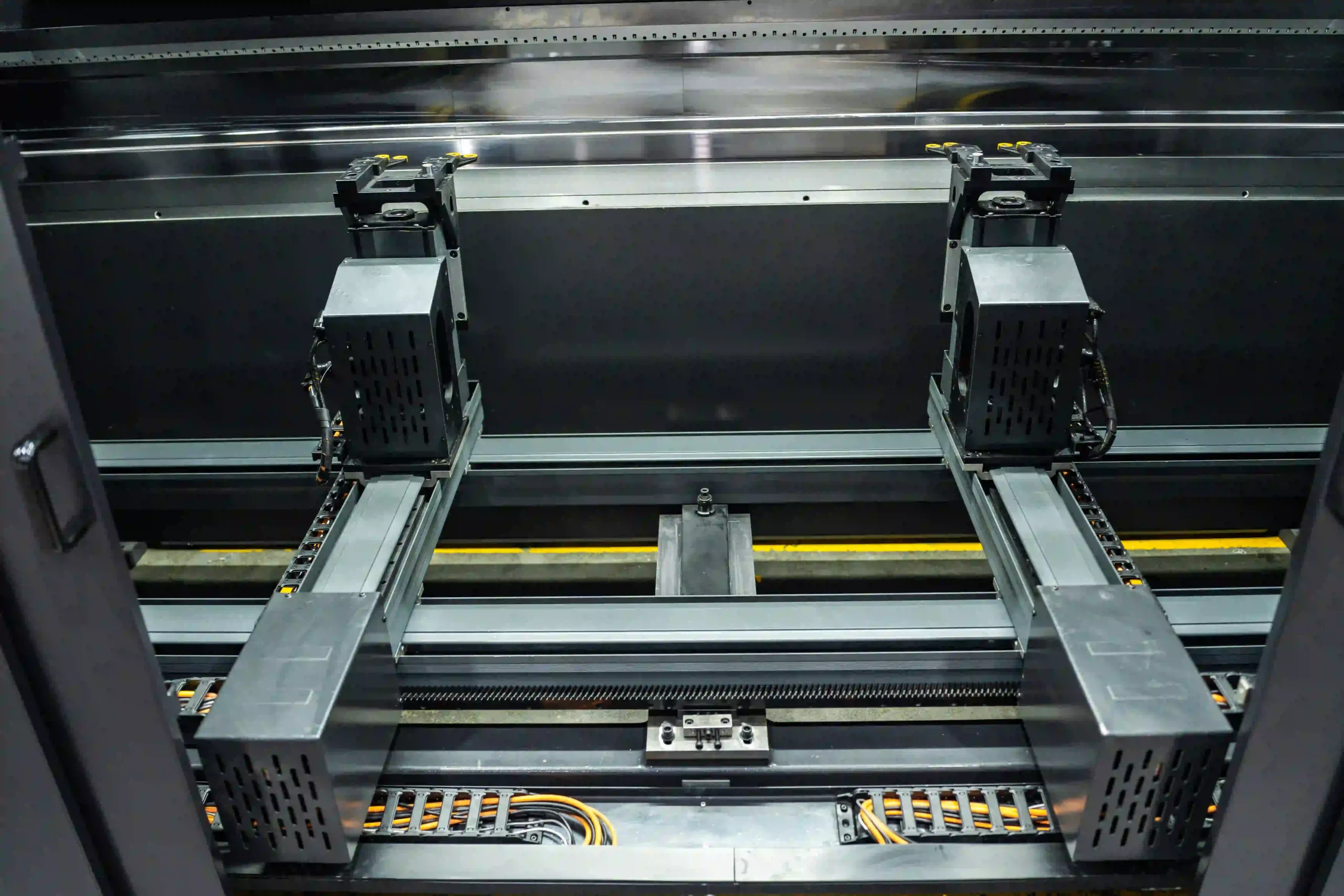

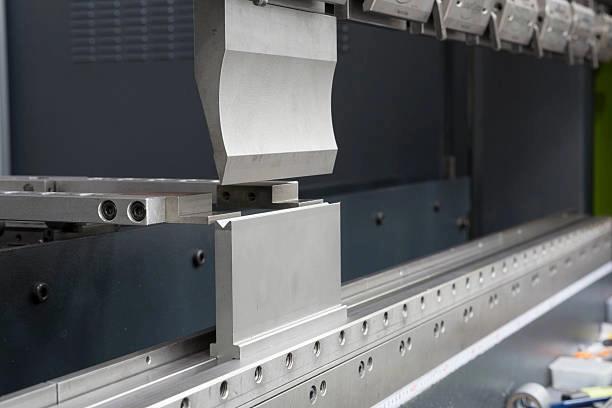

🔹 What Are Press Brake Dies?

Press brake dies are the lower tooling components in a press brake machine. They work in conjunction with press brake punches to create bends, offsets, and custom metal shapes. Choosing the right die is essential for precision and longevity in metal fabrication.

🔹 Types of Press Brake Dies

1️⃣ V-Dies

The most common type, used for air bending and bottom bending. Available in different widths to accommodate various sheet thicknesses.

2️⃣ U-Dies

Designed for U-shaped bends, ideal for round tubing and complex metal forming.

3️⃣ Offset Dies

Used for step bends, where two bends are formed in a single press.

4️⃣ Gooseneck Dies

Designed to accommodate deep flanges without interference from the punch.

5️⃣ Hemming Dies

Used to flatten edges or create double folds for added sheet metal strength.

6️⃣ Custom Dies

Manufactured for special bending applications, such as corrugated sheets, rail components, or automotive parts.

🔹 How to Choose the Right Press Brake Die?

1️⃣ Material Thickness – Thicker materials require larger V-openings.

2️⃣ Bend Angle – Choose the die angle based on the desired final shape.

3️⃣ Compatibility – Ensure the die fits your press brake tooling system 🔗.

4️⃣ Production Volume – Hardened steel dies last longer for high-volume bending.

👉 Need premium press brake dies? Explore our tooling collection 🔗.

📌 Next Article: Press Brake Tooling 🔗