1. What Is a Hydraulic Press Brake?

A hydraulic press brake is a precision sheet metal bending machine that uses hydraulic cylinders to move a ram vertically, pressing a punch into a die to form accurate bends in metal sheets. It is one of the most widely used bending tools in metal fabrication due to its power, versatility, and ease of use.

Hydraulic press brakes operate by applying pressure through hydraulic fluid, allowing for consistent, repeatable, and powerful force. The machine consists of a frame, hydraulic cylinders, ram, and precision-milled upper and lower tooling.

Compared to mechanical press brakes, hydraulic models offer smoother operation, greater safety, overload protection, and superior control over complex bending angles.

2. Types of Hydraulic Press Brakes

There are several types of hydraulic press brakes, each designed for different applications and production requirements.

● Torsion Bar Hydraulic Press Brake (Economy Type)

Also known as a manual synchro press brake, this model uses a torsion bar to synchronize the left and right cylinders. It’s affordable and suitable for small workshops or budget-conscious users.

● CNC Electro-Hydraulic Press Brake (High Precision)

This advanced type uses proportional valves and closed-loop control systems with linear scales to achieve real-time synchronization. Suitable for precision fabrication, it is widely used in automotive, aerospace, and complex bending applications.

● Heavy-Duty or High-Tonnage Hydraulic Press Brake

Built for large plate bending, typically over 300 tons, with a reinforced frame and custom tooling. Ideal for construction steel, shipbuilding, and energy industries.

● Tandem Hydraulic Press Brake (Dual-Machine Synchronized)

Two press brakes are connected via CNC to perform long bending tasks in sync. Perfect for large panels, such as elevator walls, light poles, or containers.

● Hybrid Hydraulic Press Brake

Combining electric and hydraulic technologies, this version reduces energy consumption and enhances control. Great for factories with green manufacturing standards.

● Small Hydraulic Press Brake

Compact, space-saving machines used for small part processing. Popular in kitchenware, electronics, and signage industries.

3. Advantages of Hydraulic Press Brakes

Why choose a hydraulic press brake? Here’s what makes it the go-to option in metal fabrication:

✅ Wide material range: Handles thin to thick sheets of carbon steel, stainless steel, and aluminum.

✅ Consistent bending precision, especially with CNC control

✅ Low maintenance and high durability

✅ Cost-effective for medium to large volume production

✅ High safety due to overload protection and modern light curtain systems

4. Common Applications and Industries

Hydraulic press brakes are essential tools across many sectors:

Sheet metal fabrication shops

Electrical enclosures and cabinet manufacturing

Commercial kitchens and stainless steel furniture

Elevator panels, machine frames, HVAC

Construction and architectural metalwork

5. How to Choose the Right Hydraulic Press Brake

Choosing the right press brake depends on several factors:

● Required Tonnage and Bending Length

Determine the thickness and length of your materials. For example, 3mm stainless steel over 2.5m usually requires around 100T.

● Control System (NC or CNC)

NC systems like E21 are simple and cost-effective

CNC systems like DA41T, DA53T, DA66T allow 2D/3D programming, angle correction, and automatic compensation

● Tooling and Clamping Options

Use precision ground dies for high accuracy

Consider quick-change clamping for efficiency

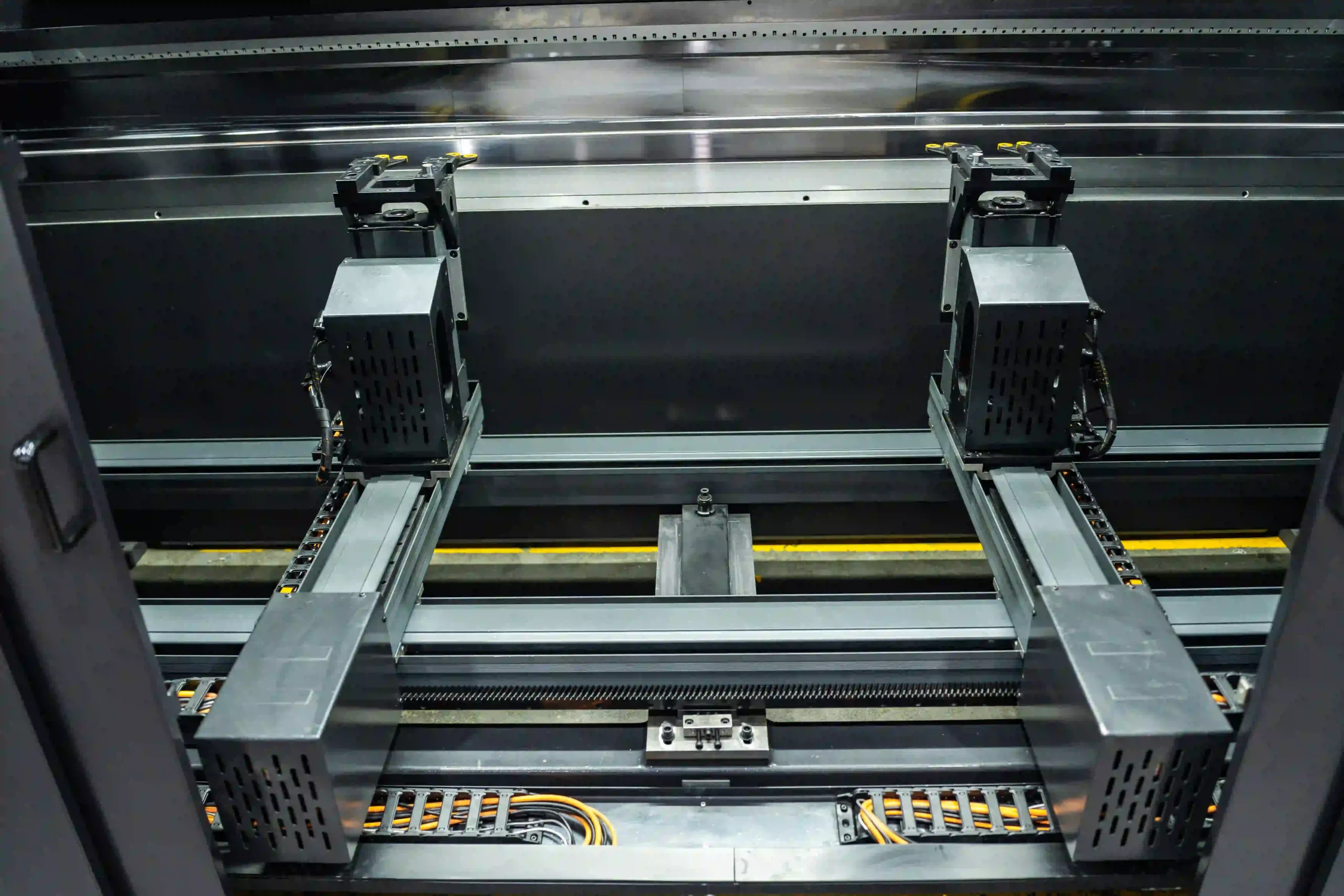

● Backgauge System

Ensure multiple axes (X, R, Z1, Z2) if you require flexibility and speed.

● Hydraulic vs Hybrid vs Electric

Hydraulic: Stable, affordable

Hybrid: Energy-saving, fast

Electric: Silent, clean, but expensive

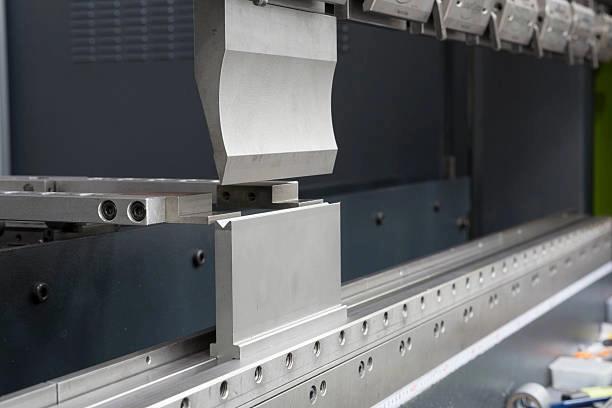

6. Hydraulic Press Brake Tooling & Dies

Your bending accuracy and material flexibility greatly depend on the quality of press brake tooling.

● Common Tooling Types:

V-dies, U-dies, gooseneck punches

Segmented tooling for complex parts

Radius tooling for large radii or scratch-free surfaces

● Materials Used:

42CrMo, GCr15, or special alloy steel

Induction-hardened, surface-ground for durability

7. Frequently Asked Questions (FAQ)

Q1: Can hydraulic press brakes bend stainless steel?

Yes, especially with sufficient tonnage and hardened tooling.

Q2: Do hydraulic press brakes leak oil?

Rarely, and only if poorly maintained. Use branded seals and routine inspections.

Q3: What’s the difference between hydraulic and electric press brakes?

Electric ones are quieter and greener but more expensive. Hydraulic is more cost-effective for general use.

Q4: How long do hydraulic press brakes last?

With proper maintenance, 10–15 years or more.

8. Why Choose MACHNIST Hydraulic Press Brakes?

✅ Over 30 Years of Experience

Established manufacturer with global recognition

✅ Factory Direct Pricing

No middleman — get high-quality machines at competitive prices

✅ Fast Delivery and After-Sales Support

Spare parts, online technical support, and training available

✅ Fully Customizable

Tonnage, length, control system, and even color options