What Is a Press Brake Tonnage Calculator?

A press brake tonnage calculator is an essential tool used to determine the required bending force for different materials, thicknesses, and bend lengths. Choosing the right tonnage is crucial to ensuring precision, preventing machine overload, and optimizing efficiency.

For industries working with sheet metal bending, selecting the proper tonnage ensures accurate bends and extends the lifespan of the equipment. If you’re using a hydraulic press brake 🔗, knowing the tonnage requirement helps you maximize performance and avoid excessive wear on the tooling.

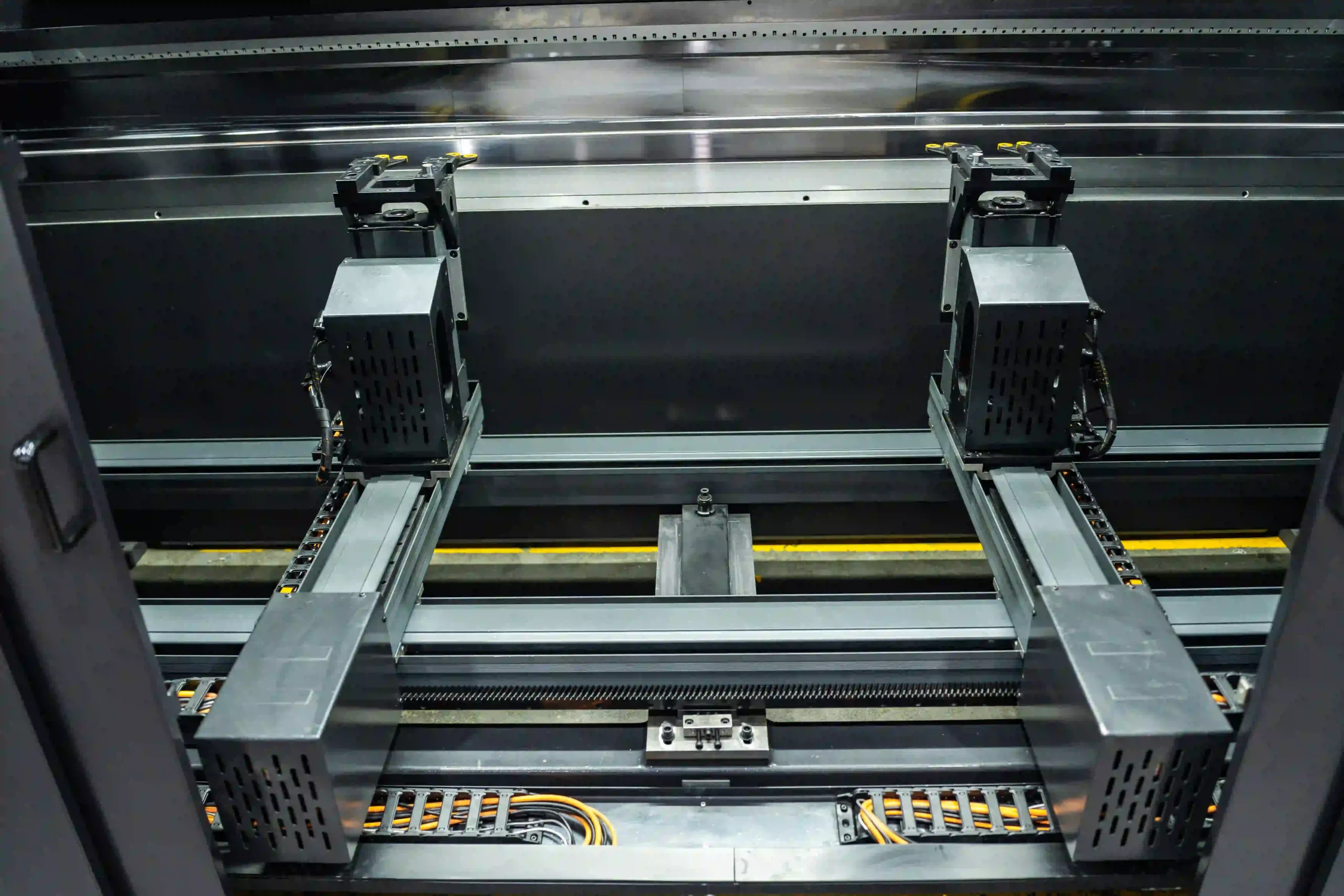

(Example of a tonnage chart used for press brakes.)

🔹 Key Factors in Calculating Press Brake Tonnage

Several factors impact the required tonnage for bending sheet metal. Let’s break them down:

1️⃣ Material Type

- Mild Steel – Standard tonnage requirements.

- Stainless Steel – Requires higher tonnage due to increased strength.

- Aluminum – Generally requires less force compared to steel.

2️⃣ Material Thickness

The thicker the material, the more force is required.

- Example: A 0.5-inch thick steel sheet requires significantly more tonnage than a 0.125-inch sheet.

3️⃣ Bend Length

The longer the bend, the greater the required tonnage. A 10-foot-long bend requires more force than a 3-foot-long bend, even with the same material thickness.

4️⃣ Die Opening Size

Larger die openings require less tonnage, while narrower dies require more force for the same material thickness.

5️⃣ Bend Angle

Sharper angles (e.g., 90° bends) need more force than larger-radius bends.

🔹 How to Use a Press Brake Tonnage Chart

A tonnage chart simplifies the calculation process. Follow these steps:

- Identify your material type.

- Find the thickness on the chart.

- Match it to the die opening used.

- Read the required tonnage per foot of bend length.

- Multiply the tonnage per foot by your total bend length.

📌 Example Calculation:

- Material: Mild Steel

- Thickness: 0.25 inches

- Die Opening: 2 inches

- Required Tonnage Per Foot: 15 tons

- Bend Length: 4 feet

- Total Required Tonnage = 15 × 4 = 60 tons

🔗 Related Topic: Learn more about press brake tooling 🔗 (Link to Press Brake Tooling Article).

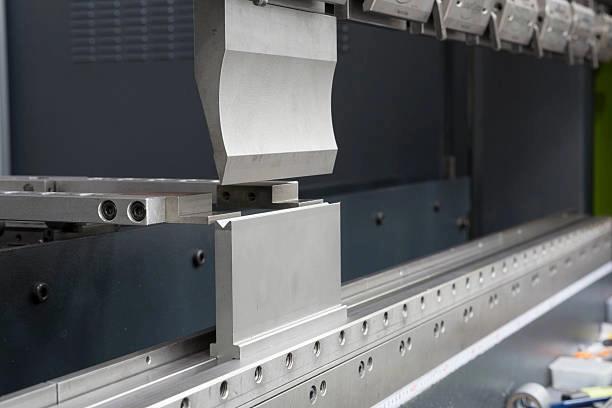

(Example of a press brake tonnage chart for different materials.)

🔹 Press Brake Tonnage Calculator vs. Manual Calculation

✔️ Benefits of a Tonnage Calculator

✅ Eliminates human error

✅ Saves time

✅ Ensures machine safety

❌ Downsides of Manual Calculation

❌ Risk of miscalculations

❌ Requires reference charts

❌ Slower process

If you’re frequently adjusting tonnage, consider using a digital press brake control to simplify the process. Many modern CNC press brakes 🔗 have built-in tonnage calculation features.

🔹 Choosing the Right Press Brake for Your Tonnage Needs

Selecting a press brake that meets your tonnage requirements is critical. Here are some recommendations:

- For light sheet metal (under 0.125″) → A small press brake 🔗 is ideal.

- For mid-range applications (0.25″-0.5″) → Consider a hydraulic press brake 🔗.

- For heavy-duty bending (1″+ thick steel) → A high-tonnage CNC press brake 🔗 is required.

🔹 Conclusion

A press brake tonnage calculator helps manufacturers select the right equipment, prevent machine strain, and achieve precision bending. Whether you’re working with mild steel, stainless steel, or aluminum, calculating tonnage correctly ensures efficiency and safety.

👉 Explore our full range of press brakes here 🔗

👉 Next Article: Press Brake Manufacturers 🔗